- Home

- All Products

- Construction Excavators

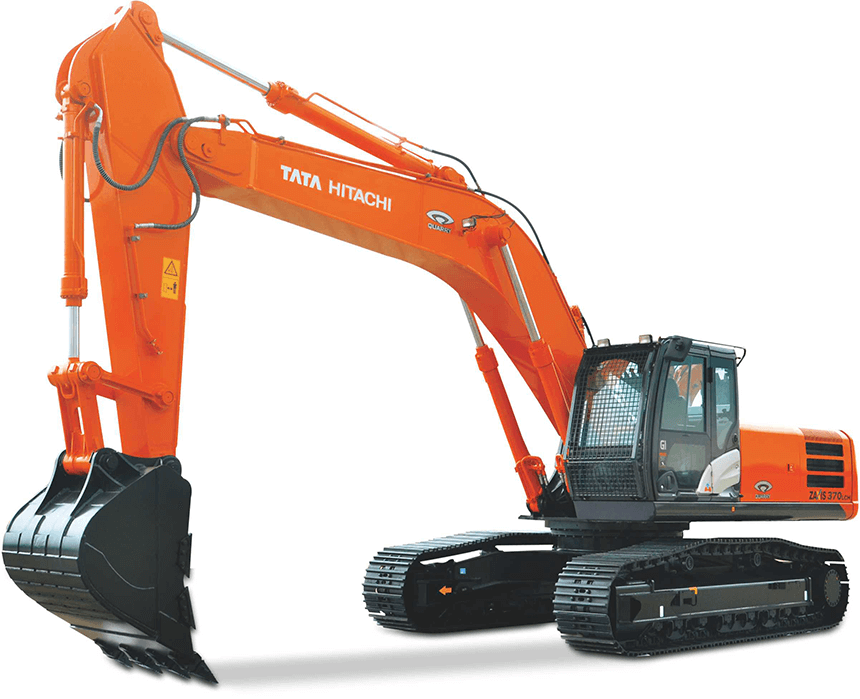

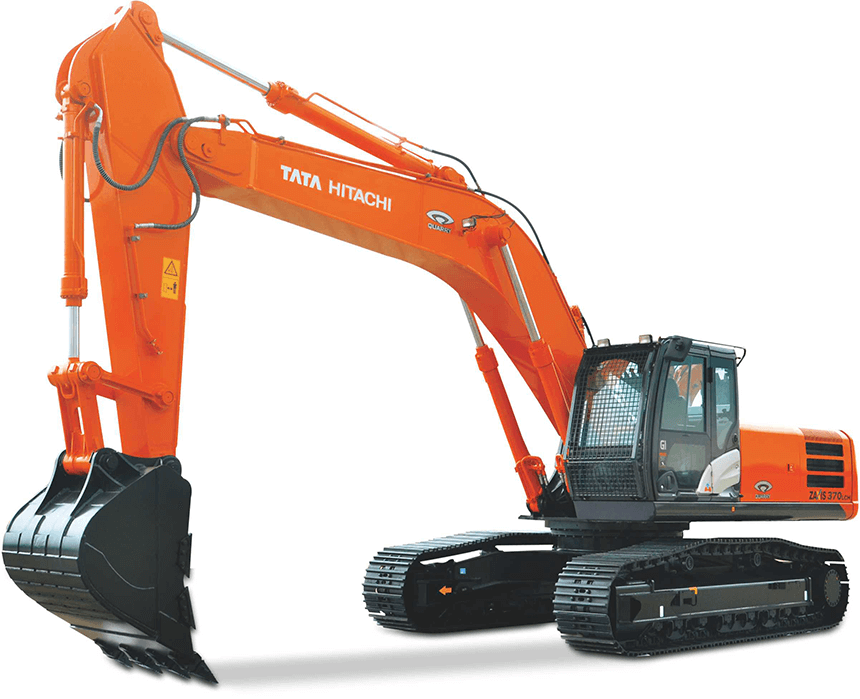

- ZAXIS 370LCH

OVERVIEW

The ZAXIS 370LCH GI Series excavator is designed and manufactured for working in granite, marble quarrying and other heavy duty applications. Retaining the ruggedness, a variant of the machine has been made for bulk excavation as well.

FEATURES

ROCK SOLID, DURABLE FRONT ATTACHMENT

The front attachment is manufactured to perfection using state-of-the-art robots and computer controlled machines. The boom top and bottom are strengthened using high tensile steel. Steel plates of higher size and thickness are used in the arm to make it stronger and more durable. A reinforced resin thrust plate, mounted on the bucket pin, helps reduce noise.

Arm cylinder & boom cylinders (rod extend ends) cushion shocks at stroke end to cut noise and extend service life. Joint pins at the front attachment are tightly fit to reduce jerk and sound.

REMOTE FLEET MANAGEMENT

Remote Fleet Management with Global e-Service.

Provides easy access to machine on the site, conveying operating information and log, including machine location, daily operating hours, fuel level, temperatures, pressures and likes.

MORE PRODUCTION WITH LESS FUEL

- 10% Reduction in fuel consumption

- More fuel reduction in the ECO MODE

- Swift front movements with HIOS* III hydraulics

- Powerful lifting operation

- Boosted swing torque

- Enhanced power boost

- Easy to use attachments

MONITOR YOUR MACHINES CLOSELY WITH CONSITE

ConSite is a consolidated solution service that links you to your machines on the construction site.

DURABLE RELIABLE ENGINE

This engine has a track record showing impressive durability at countless tough job sites around the world.

The engine features a rugged design, a direct fuel injection system and an elaborate governor make it more sustainable and help it comply with EU Stage II and US EPA Tier 2 emissions regulations.

The cooling system, well keeps the engine cool. The engine cover has wider air suction area, and radiators are arranged in parallel for efficient cooling. Their parallel arrangement also facilitates cleaning.

The ample capacity intercooler and turbocharger help yield a whopping 250 PS (125 KW) output for higher production in shorter job schedule.

SIMPLIFIED MAINTENANCE

Parallel arrangement of ROC, dustproof indoor net, grouped remote inspection points, sloped side frame tops, long service intervals and electric fuel filling pump helps to simplify maintenance.

OPERATOR SEAT – DESIGNED FOR COMFORT

The user-friendly suspension seat is fitted with a headrest and armrests for operative comfort.

It can be adjusted in multiple ways, sliding and reclining, to suit operator’s size and preferences.

The seat can slide rearward by 40 mm more for added leg space.

STRENGTHENED UNDERCARRIAGE

- The X-Beam frame is made monolithically with fewer welds for higher rigidity & durability.

- Track adjusters absorb impacts to crawlers. Front idlers and adjuster cylinders are integrated to increase durability.

- Idler brackets and travel motor brackets are both thickened for added durability.